roughing end mill feeds and speeds

Many tooling manufacturers provide useful speeds and feeds charts calculated specifically for their products. It will give you.

Speed Feed General Purpose End Mills Melin Tool Company

Java version 180_66 JavaTM SE Runtime Environment build 180_66-b17 Java HotSpotTM 64-Bit Server VM build 2566-b17 mixed mode.

. For even more details on those special tasks that complement CAM check out 37 Things CAM Wont Do For You That G-Code Programming Can. CNC ground in the USA. At one end of the bed almost always the left as the operator faces the lathe is a headstock.

With higher flute counts it would become difficult to evacuate chips effectively at the high speeds at which you can run in aluminum. 40 is the default which is good for most general pocketing and roughing passes when carving 3D objects. Whats the Best Way to Learn G-Code.

Rotating within the bearings is a horizontal axle with an axis parallel to the bed called the spindle. The program will recommend the ideal solid carbide end mill slitting saw or PCD and diamond coated tool for your application. This is because aluminum alloys leave a large chip and chip valleys become smaller with each additional flute on an end mill.

Carbide HSS Cobalt. FULL PRODUCT VERSION. The headstock contains high-precision spinning bearings.

Adventures In Datingspotlight On Pink Cupid - Popdust. The cutter rotates at high speed and because of the many cutting edges it removes metal at a very fast rate. The software will also pick the best PVD coating for the job including AlTiN TiCN TiN DLC and diamond coatings.

The best way to learn G-Code is slow. A simple feeds and speeds change in the gcode will handle it far faster than re-running the CAM assuming were capable of making such simple changes. Feeds is feedrate on some CNCs with a fixed tool and moving plate this is the speed at which the material is fed into the cutter on a Shapeoko Since the feedrateRPM combination is derived from the desired chipload value lets first have a look at what the range of acceptable chipload values is for.

Milling is the machining process in which the removal of metal takes place due to the cutting action of a rotating milling cutterIn a milling machine the cutter is rotating due to workpiece is fed against itThis machine can hold more than one tool at a time. Our feed rate will be 60. End mills for aluminum are often available in either 2 flute or 3 flute styles.

Spindles are often hollow and have an interior Morse taper on the spindle nose ie facing to the right towards the bed by which. A customer can find the SFM for the material on the left in this case 304 stainless steel. The chip load per tooth can be found by.

We are a store where you can easily find and purchase High Quality End Mill Bits including high performance Solid Carbide EndmillsWe have broken the industrial tool catalog paradigm by creating two fast and easy methods to search for your milling BitYou can use the categories on the left or you can use the End mill filter search. What is rapid traverse feed rate. The speed and feed calculator provides over 50 years of machining experience to give the best speeds and feeds possible.

Opyright 2019 ideo ll ights eserved ostenlose ornofilme und ratis obile ornos eutschsex ontakteschreibung ier auf eutschsex findest u ama iebt inen ungen chwanz n hrer otze nd em rsch und jede enge gratis ornos. When making finish passes you would reduce this number to 10 especially when using a 116 ball nose end mill for detail carving. Aplus coating offers added lubricity and high temperature resistance for faster speeds and feeds and improved tool life.

For example Harvey Tool provides the following chart for a 18 diameter end mill tool 50308.

Circular Interpolation Circular End Mill Linear

Speed Feed Recs Melin Tool Company

Bb 3 Flute Carbide Milling Cutter Tungsten End Mill Cnc Tool 1 To 20mm Hrc55 For Aluminum Fiberglass Acrylic Wood Copper Plastic Milling Cutter Aliexpress

Colton Cutting Tools 61127 Carbide End Mill 2 Flute Square End Standard 1 16 Diameter X 1 4 Loc X 1 1 2 Oal All Industrial Tool Supply

Speed Feed Recs Melin Tool Company

Yg 1 E9990tf High Speed Steel Hss Square Nose End Mill Weldon Shank Tialn Multilayer Finish Roughing Cut Non Center Cutting 30 Deg Helix 4 Flutes 3 875 Overall Length 0 75 Cutting Diameter 0 75 Shank

Osg Taps End Mills Drills Indexable Composite Tooling Diamond Coating Die Products Hss Co Roughing

Speed And Feeds For High Speed Steel And Cobalt End Mills

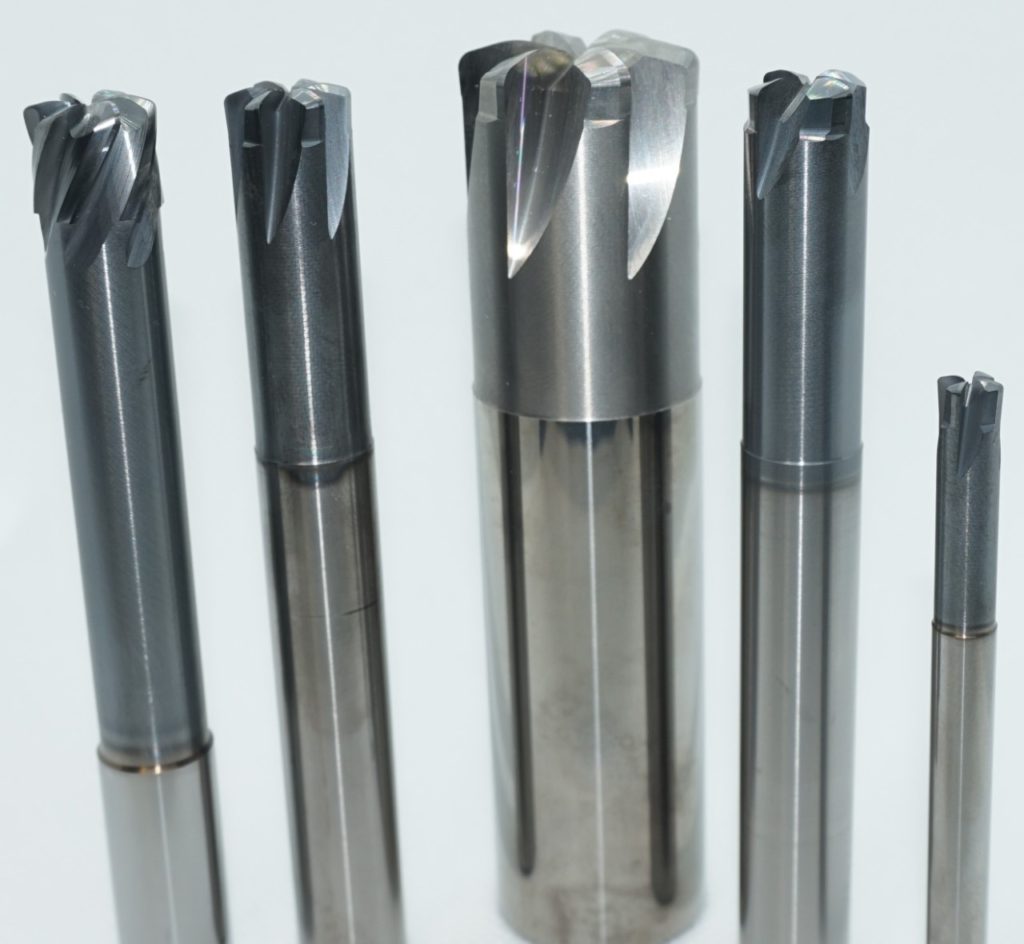

What To Know When Selecting An End Mill End Mill The Selection Machining Process

Multiple Uses Of Chamfers Multiple Cost Saving Canning

7 Tips For Choosing The Right End Mill For The Job M M Sales Equipment

8 Ways You Re Killing Your End Mill In The Loupe

Speed Feed Recs Melin Tool Company

4 6 Flute High Feed End Mills Epic Tool

Speed Feed Recs Melin Tool Company

Yg1 E5g95016 1 4 Diameter X 1 4 Shank X 3 8 Loc X 2 Oal Alu Power H 37 3 Flute High Performance Carbide Square End Mill All Industrial Tool Supply

Speed Feed Recs Melin Tool Company

Speed Feed Recs Melin Tool Company

Kennametal 12mm Diam 6 Flute Solid Carbide 3mm Corner Radius End Mill 33241449 Msc Industrial Supply